Designed for manufacturing candies of various colors and types, such as two-color candy, filled candy, and spiral candy, the hard candy depositing production line

features a maximum capacity of a massive 1200kg/h. This production line consists of an automatic weighing system, vacuum cooker, cooling system, and demolding device.

By simply changing molds and other parts of the production line, it can be used to produce hard candies of various shapes, such as spherical hard candies,

flat hard candies, and 3D hard candies.

The entire production process is computer controlled which ensures the finished candies are precisely the right size, shape, and weight.

We are the original hard candy depositing production line manufacturer in China.

Our production lines have been applied and praised by many customers around the world. Contact us to learn more.

The heating time, heating temperature, depositing time and depositing speed is controlled by computer.

10.7 inch touch screen displays various parameters including flow charts, the status of each part of the production line, temperature, depositing speed, etc.

Flow of the syrup is precisely controlled by frequency control system that ensures stability.

Depositing Way Hard Flat and Ball Lollipop Candy Making Machine |

Model | GY-GD150 | GY-GD300 | GY-GD450 | GY-GD600 |

Capacity | 150kg/hr | 300kg/hr | 450kg/hr | 600kg/hr |

Candy Weight | |

Depositing Speed | 55 ~65n/min | 55 ~65n/min | 55 ~65n/min | 55 ~65n/min |

Steam Requirement | 0.2m³/min,

0.4~0.6Mpa | 0.2m³/min,

0.4~0.6Mpa | 0.25m³/min,

0.4~0.6Mpa

| 0.25m³/min,

0.4~0.6Mpa |

Mould | We have different shape of mould, In our Production Design you can produce different shape hard candy in the same line and in the same time in the same day. 1. our mould is the best mould, we use advanced equipment to produce it with super high temperature and high pressure, it is not easy to stick candy. |

Dissolving tank

A. Dissolving tank total volume: 300LB. Mixer motor power 0.75KwC. Equip with valve, steam trap, pressure meter, safety valveD. Steam consumption: 100kg/h, pressure: 0.5MpaE. Machine made of SUS304 material (except standard parts)F. Machine size (L*W*H): 1100*1100*1400 mmG. Machine weight: 100Kg

Transfer pump

A. Gear pump head diameter: 1”, motor power: 1.5KwB. Pump head made of SUS304 materialC. Include inlet and outlet SUS304 pipeD. Machine size (L*W*H): 560*250*250mmE. Machine weight: 40Kg

Storage tank

A. Storage tank total volume: 200LB. Mixer motor power: 0.75KwC. Equip with syrup filter net, SUS304 outlet pipeD. Machine made of SUS304E. Machine size (L*W*H):650*650*1350mmF. Machine weight: 120Kg

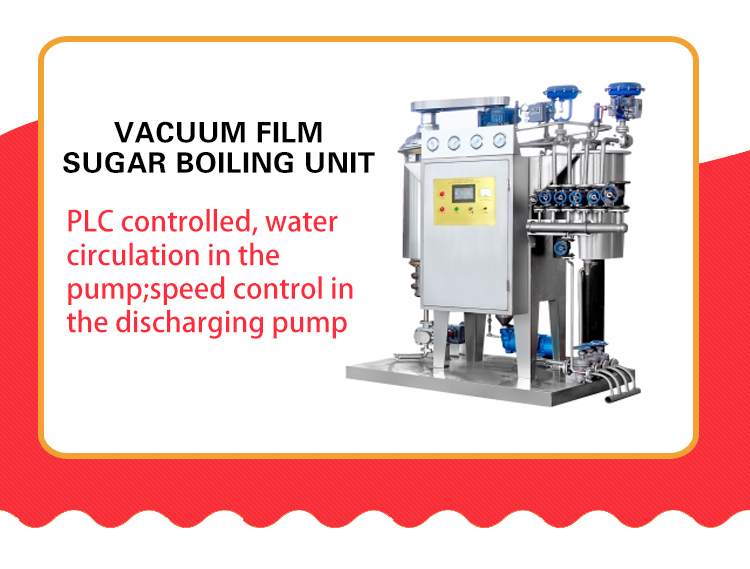

Micro-film Cooker

A. Piston dosing pump: 1set, motor power 0.75Kw

B. Preheater 1setC. Vacuum pump 1set, motor power 4Kw,

including SUS304 piping system 1setD. Micro film generator 1set, power:4Kw

E. Discharge pump 1set, motor power 1.5Kw, speed adjustable, including SUS304 insulation piping system 1setF. Steam control system 3sets (preheating, cooking, heat preservation) pipe material: all use SUS304 high pressure resistant pipeG. Electrical control use PLC, large screen etc centralized control

H. Whole machine steam consumption: 200kg/h,

steam pressure: 0.6MpaI. Machine made of SUS304 material (except standard structural parts)J. Machine size: 2.1*1.6*2.25 mK. Machine weight: 900kg

Servo system Depositing & cooling (One row without A/C)

A. Double color servo depositor 1set, servo motor: 1.5Kw X 2sets B. Depositor head automatic tracking use servo motor control, power 1KwC. Depositor electrical control: 5-route temp. controller, power 5.5 Kw.D. Mold conveyor power: 1.5Kw, use inverter adjust speedE. Syrup color & flavor mixer 2sets, power 0.37KwF. Flavor and color dosing 4sets, flow rate 3L/h(Max), flow rate adjustable

G. Cooling tunnel belt 1set, conveyor 0.75KwH. Machine made of SUS304 material (except transmission shaft, cam, chain, gears and related standard configuration parts)

Ball lollipop stick-insert machine

A. Stick insert speed: 28 n/minB. Lollipop diameter: 28mm(max)C. Lollipop weight: 26g(max)D. Stick length 60-100mm