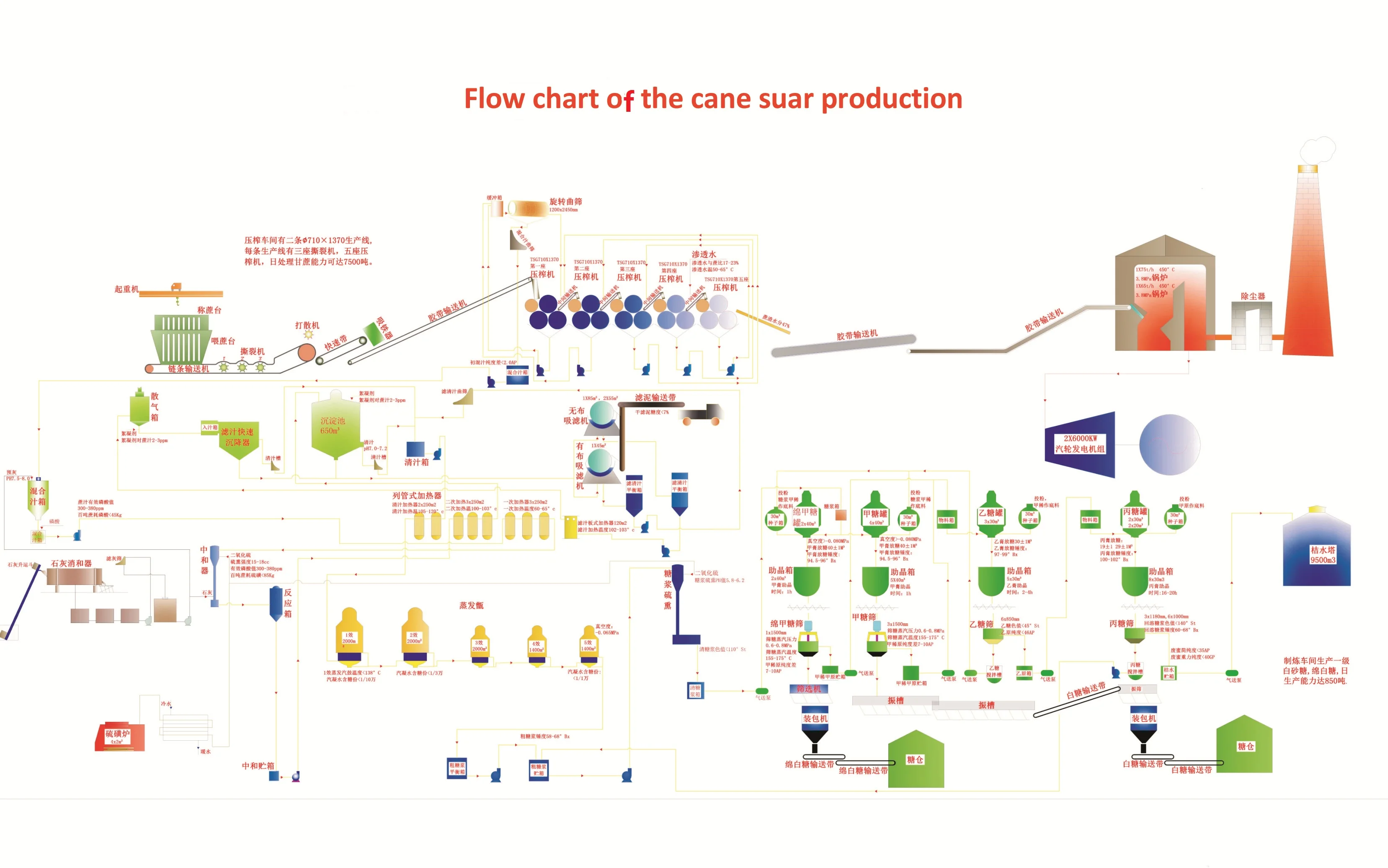

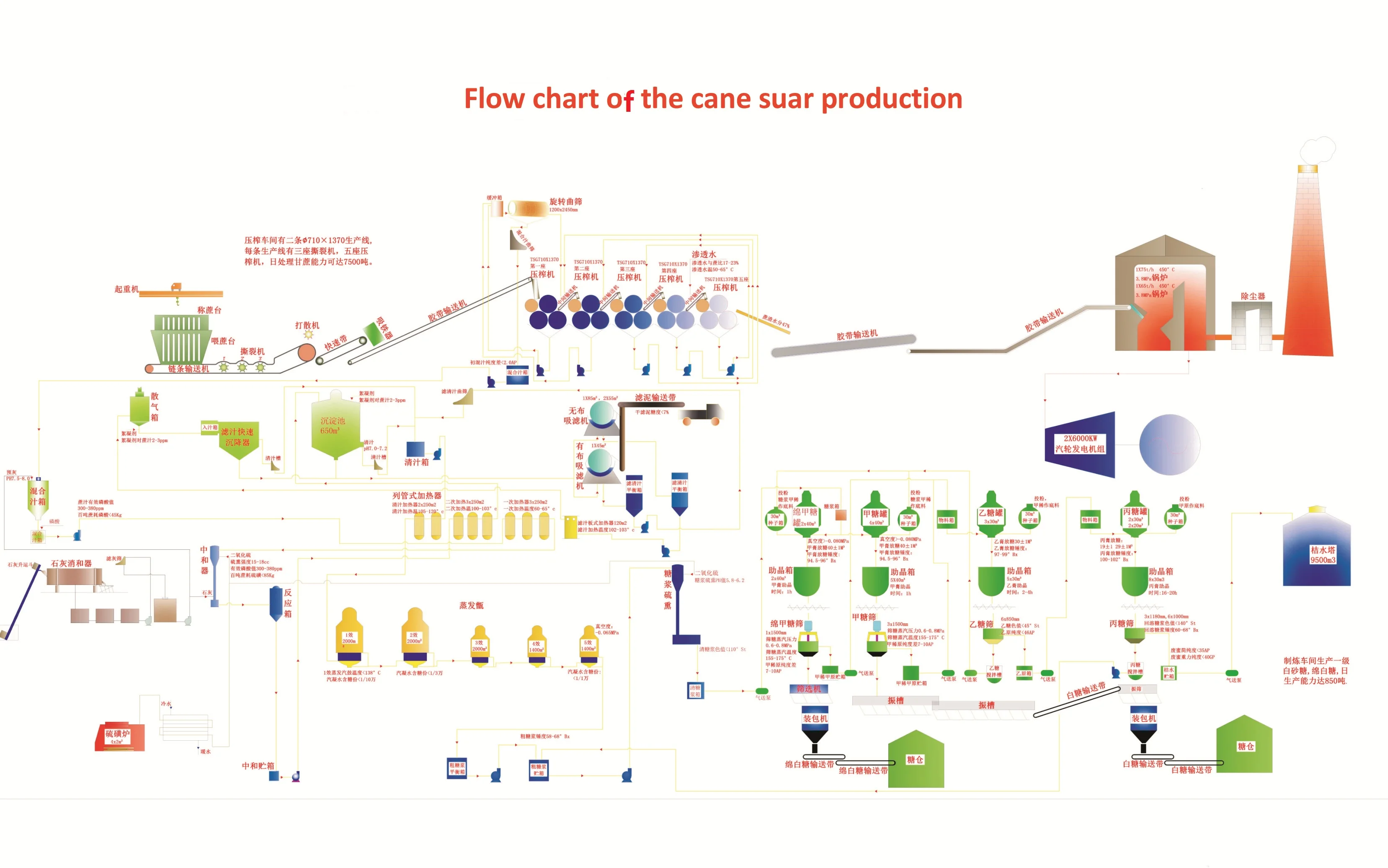

sugar processing production line

![]()

Main settings

SN | Description |

I | Production shop |

1 | Lifting and discharging house |

2 | Raw sugar house |

3 | Mill house |

4 | Boiling house |

5 | Lime house |

6 | Laboratory |

7 | Service shop |

8 | Boiler room |

9 | Power house |

10 | Electric system |

11 | Instrument control |

12 | Water supply and drainage system in workroom |

13 | Non-standard equipment |

14 | Equipment and materials for erection and installation |

15 | Spare parts for two year |

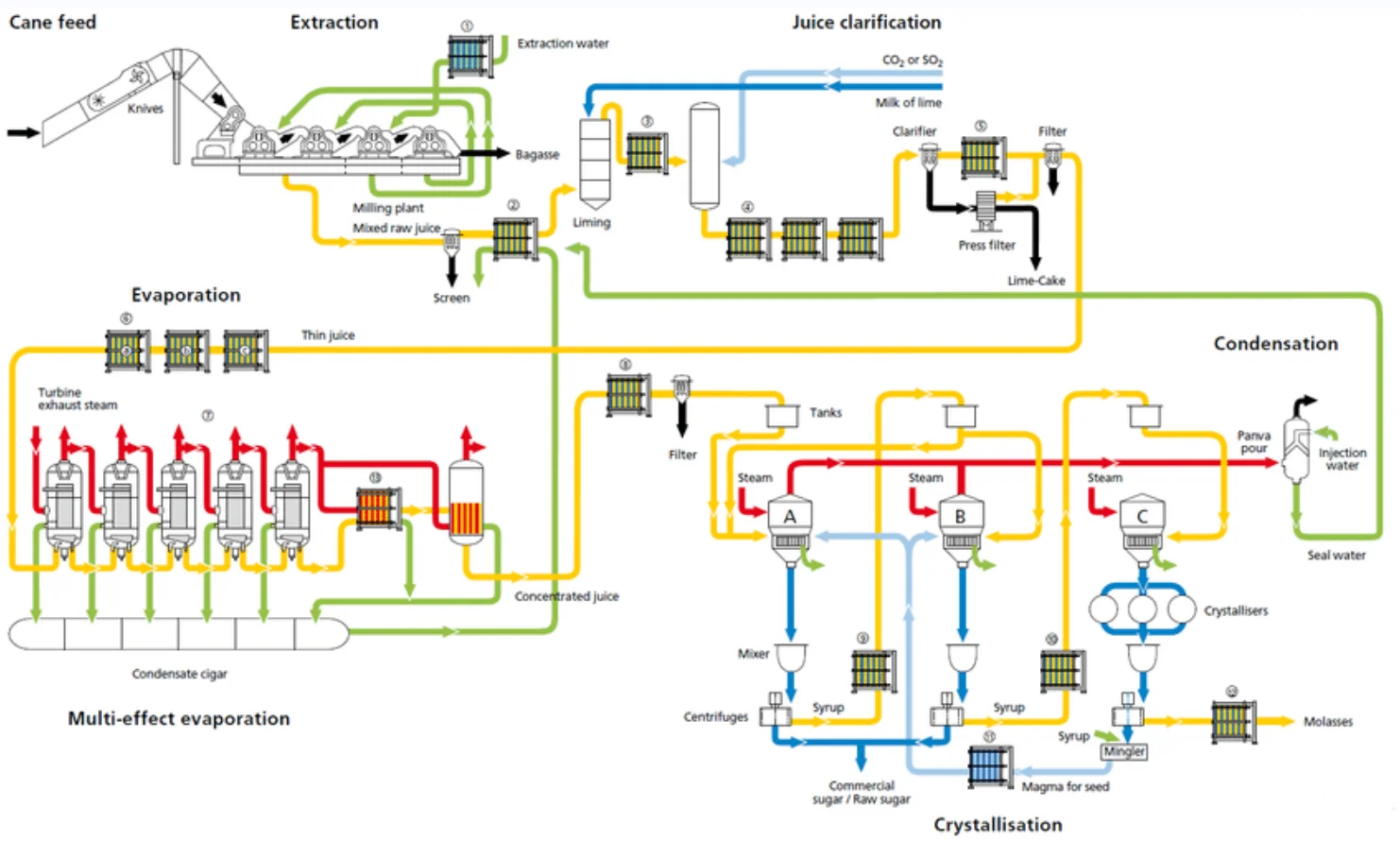

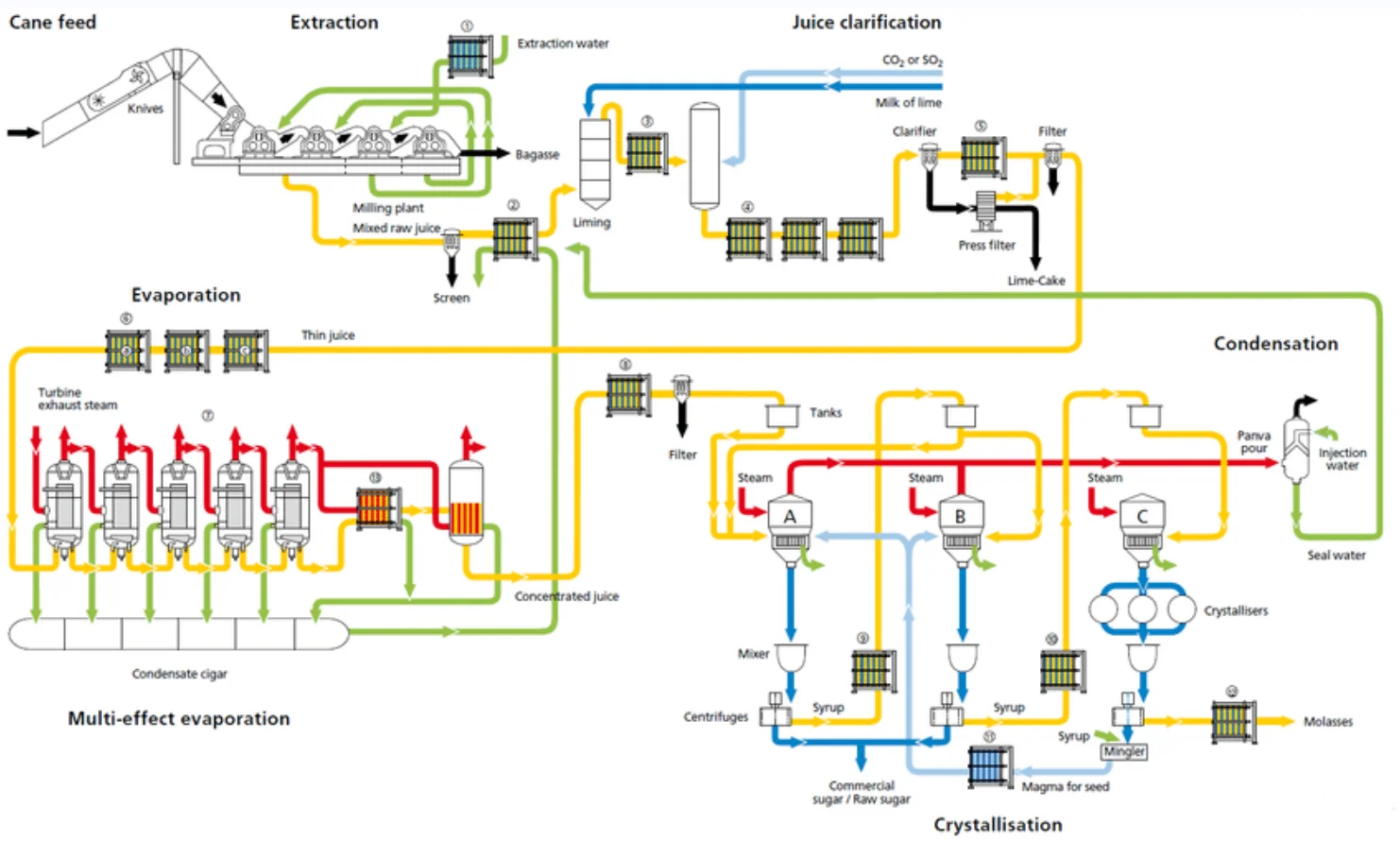

technologies that are now the reference standard for the industry:

Cane Carrier

This is used to transport cane to the milling tandem, and consists of chains and slats. Its width is normally equal to the mill size.

Mill

A cane-crushing unit having normally consisting of three rollers in a heavy steel housing. Cane first passes between the top and front rollers, then between the top and back rollers,

to extract the juice.

Crushers

A cane crushing unit, preceding the first mill to crush the cane prior to extraction of juice, for the purpose of improving the quantity of juice extracted. Normally consists of two rollers.

Shredder

This has the same purpose as the crusher, but a different principle. Consists of a drum, with a concentric shaft, on which hammers are mounted on arms.

Mill Tandem

A complete mill is complex, consisting of crusher (or shredder) and all mills, together with drives and reducing gears.

Cane Knives

These are mounted on cane carriers prior to entrance to mills, for preventing entire cane stalks from entering the mills, straightening and precutting the cane, for the purpose

of improving juice extraction and saving driving power at the same time.

Intermediate Carriers

These transport the milled cane (bagasse) from one mill to the next. BAGASSE CARRIER This carries the bagasse from the last mill to the boilers, and its excess to storage.

Power Plant

This produces electricity by means of non-condensing steam turbines, which drive generators.

Juice Heater

A heat exchanger in which juice is heated by using steam as a medium, normally a multi-pass system. Juice flows through tubes, while steam passes along the outside of the tubes,

in the cylindrical body.

Clarifier

It is a large vertical cylindrical tank, where juice is given time for decantation, to separate the clear juice from the turbid, which still contains the mud. Juice flow is continuous.

Drum Filter

A device to separate the mud from the turbid juice; normally of the rotary vacuum type. , to let the juice pass and retain the mud on its surface.

Evaporator

A series of vessels, in which excess water from the juice is evaporated to form a more concentrated liquid, now called syrup. The vessels work in series under increasing vacuum conditions,

to reduce the boiling temperature gradually as the concentration increases step-wise. This prevents overheating of juice and loss of sucrose. The vessels together form a triple-,

quadruple- or quintuple-effect evaporator.

Vacuum Pan

Similar to an evaporator vessel, a continuation of the evaporating process, but carried so far that crystallization occurs. Also boils under vacuum for reduced boiling temperature.

The syrup is now transformed into massecuite , which is a mixture of crystals and molasses.

Crystallizer

A strike receiver in which the charge from the vacuum pan is stored before going to the centrifugals. Its purpose is cooling, to increase grain size and reduce sucrose left in molasses.

Centrifugal

A machine with a fast spinning drum and a screen, inside, through which the molasses can pass while the crystals are retained. Separation is based on the difference in specific gravity,

amplified by centrifugal force.

Dryer

A long drum-like rotating cylinder, where sugar is brought in contact with heated air, to reduce its moisture content.

Cooler

Same as a dryer, but air is dry and cooled to reduce temperature of sugar, heated by the dryer. This is to prevent caking during storage. The combination of dryer an

Scope of Supply

Feasibility Studies

Plant Design

Material and Equipment Supply

Construction, Installation and Supervision

Commissioning and Start-Up

Training and operation