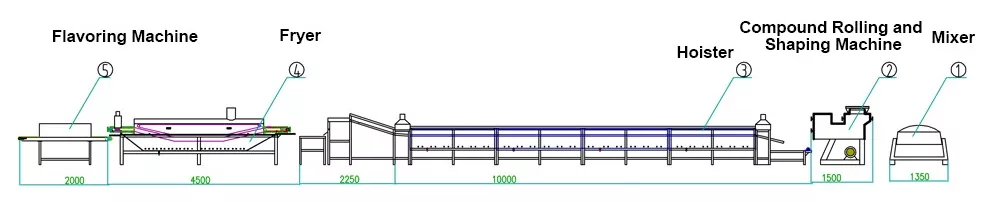

1. Mixing

Use a flour mixing machine to mix flour and water. The amount of water added per 1kg of flour is 0.3~0.4㎏. The temperature is 20-30°C, and the stirring time is 15-20 minutes.

The dough produced in this process is called "dough", which is composed of a fine mesh structure and forms the "glutinous" of the dough.

2. Compound

The formation of dough sheet. The dough is passed between the two rotating rolls to first make two dough sheets, and then combine them into one. In this process,

the dough sheet is made strong and uniform. Before the two dough pieces are combined, the dough is sometimes aged for a period of time.

3. Calendering

Use a pressing roller to press a dough sheet with a thickness of about 10mm to make it thinner to about 1mm. In this process, the mesh structure of the surface is strengthened to strengthen the "tendons"

4. Cutting

After pressing, the dough sheet enters the cutting stage. Rotate the cutter, and the noodles become noodles.

5. Steaming

The noodles are steamed through a continuous steamer. It is usually steamed at 100°C for 5 to 10 minutes. Here, the starch in the noodles becomes digestible.

6. Cut off and inputs

The noodles are cut and shaped here. The length is generally 40 to 70 cm.

7. Frying

Fry the noodles together with the metal frame in edible oil at 150-170°C for 1 to 2 minutes. In the dough stage, the water content of 30-40% becomes 3 to 6%, and the starch is further gelatinized.

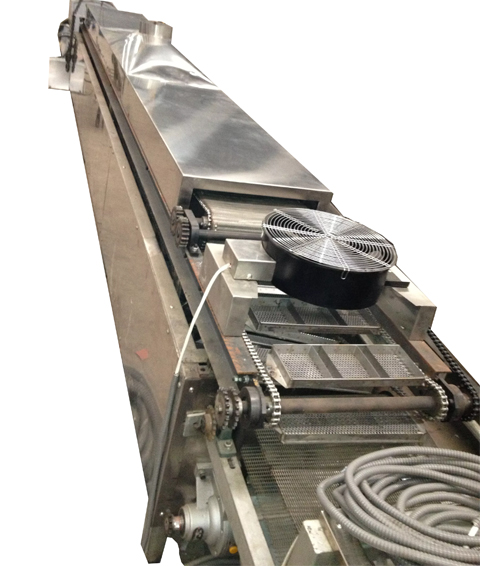

8. Cooling

Blow the noodles with cold air to cool. After that, check the weight, shape, color, dryness, fried state, cooling temperature,etc.