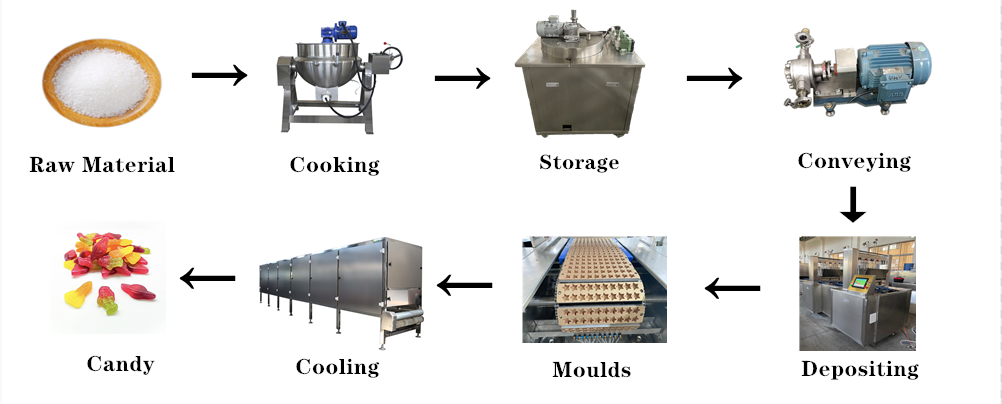

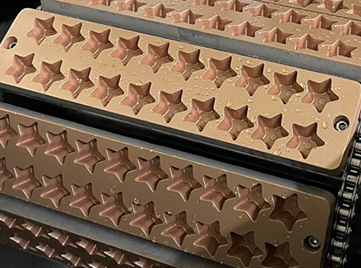

The company supplies all kinds of automatic candy complete sets of equipment, integrating machine, electricity and gas control, with a reasonable and compact structure and a degree of automation. With high production efficiency, it can produce single-color, dual-flavor two-color spray, dual-flavor dual-color double-layer, three-flavor three-color spray, crystal candy, filling candy, striped candy, and thinking. The candy produced by the hard candy pouring production line has the characteristics of crystal clear and smooth, clear spray pattern, accurate and stable filling amount and position, and good taste. It is well received by customers at home and abroad. The entire production line is manufactured in accordance with food machinery standards and meets food hygiene requirements, making it easy for food companies to pass food certification.